My experiences in my <Robot Devices Kinematics Dynamics and Control>, <Algorithms for Sensor Based Robotics>, and <Robot System Programming> courses this past year forged a bond between me and the UR5 robot arms—we had gone through so much together! So once I returned home for the summer, I deeply felt the absence of my old pal and needed to do something about it.

After justifying the project to my brother by trivializing the challenges and glorifying the end results, I earned myself a partner in building our very own robot arm. Eric and I spent many weeks researching what goes into building and controlling a robot arm, eventually forming an idea of what we wanted to design.

The goal of this project was to manufacture a desktop robot arm with the purpose of exploring different control methods—particularly learning-based control.

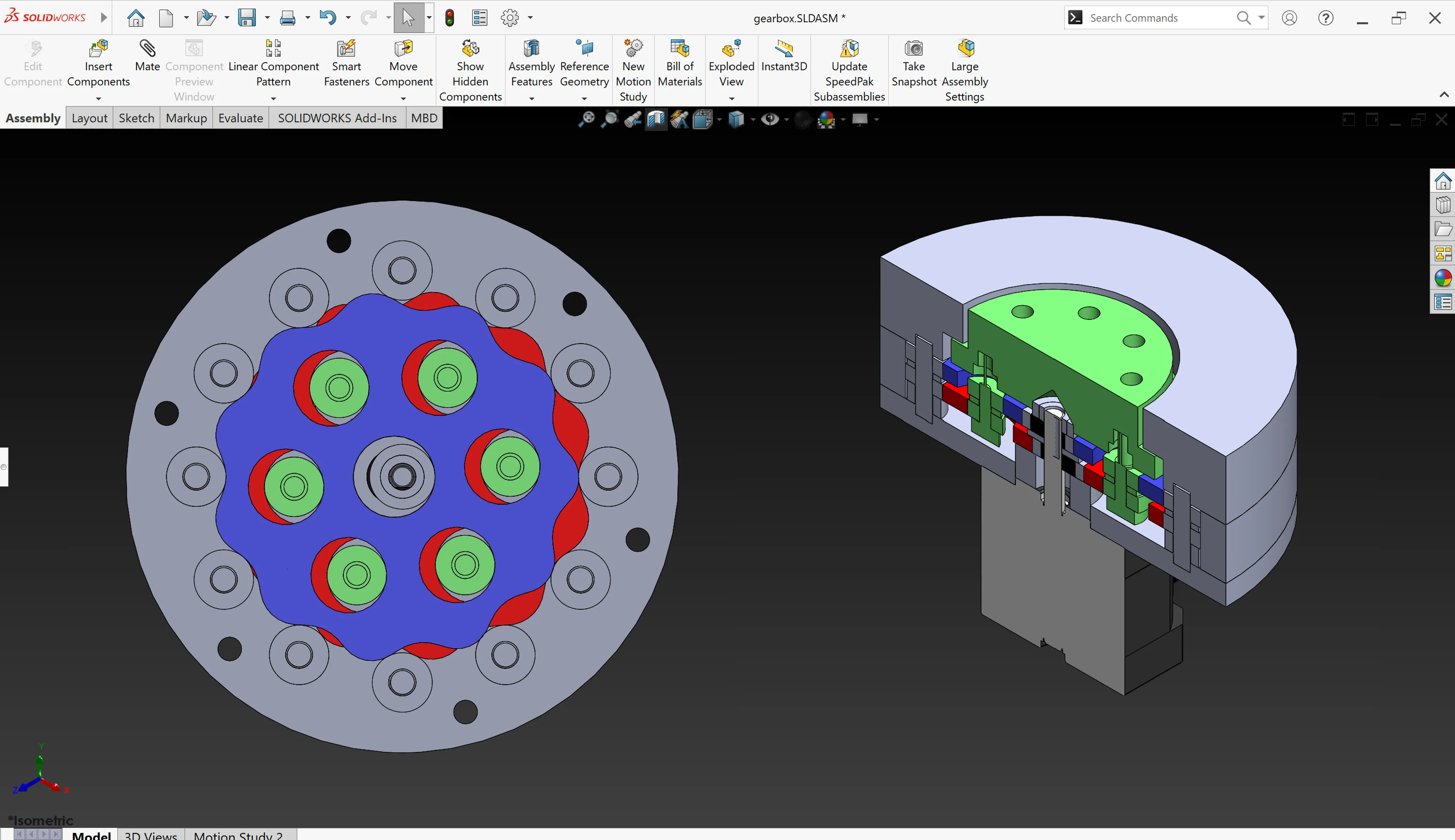

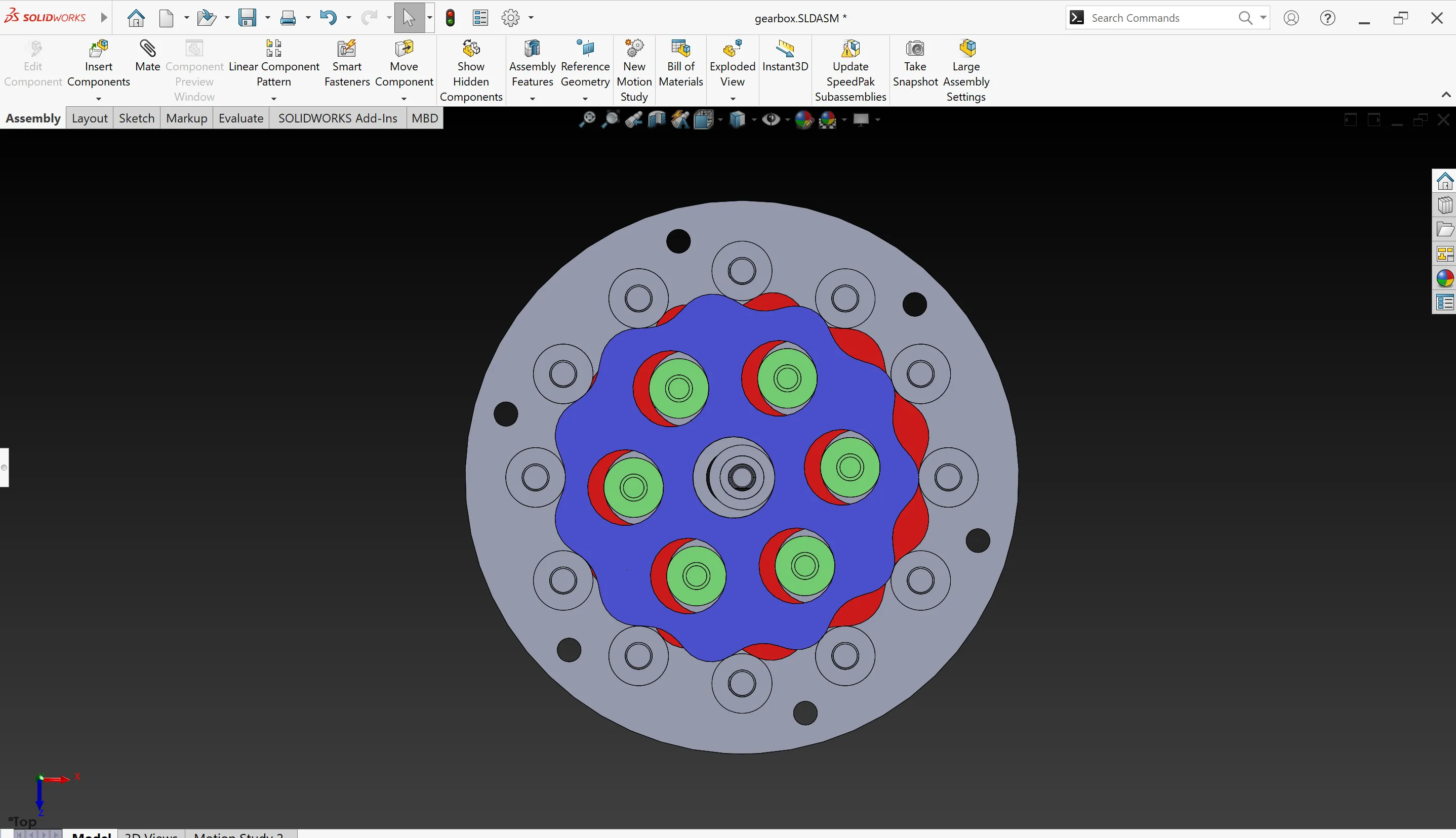

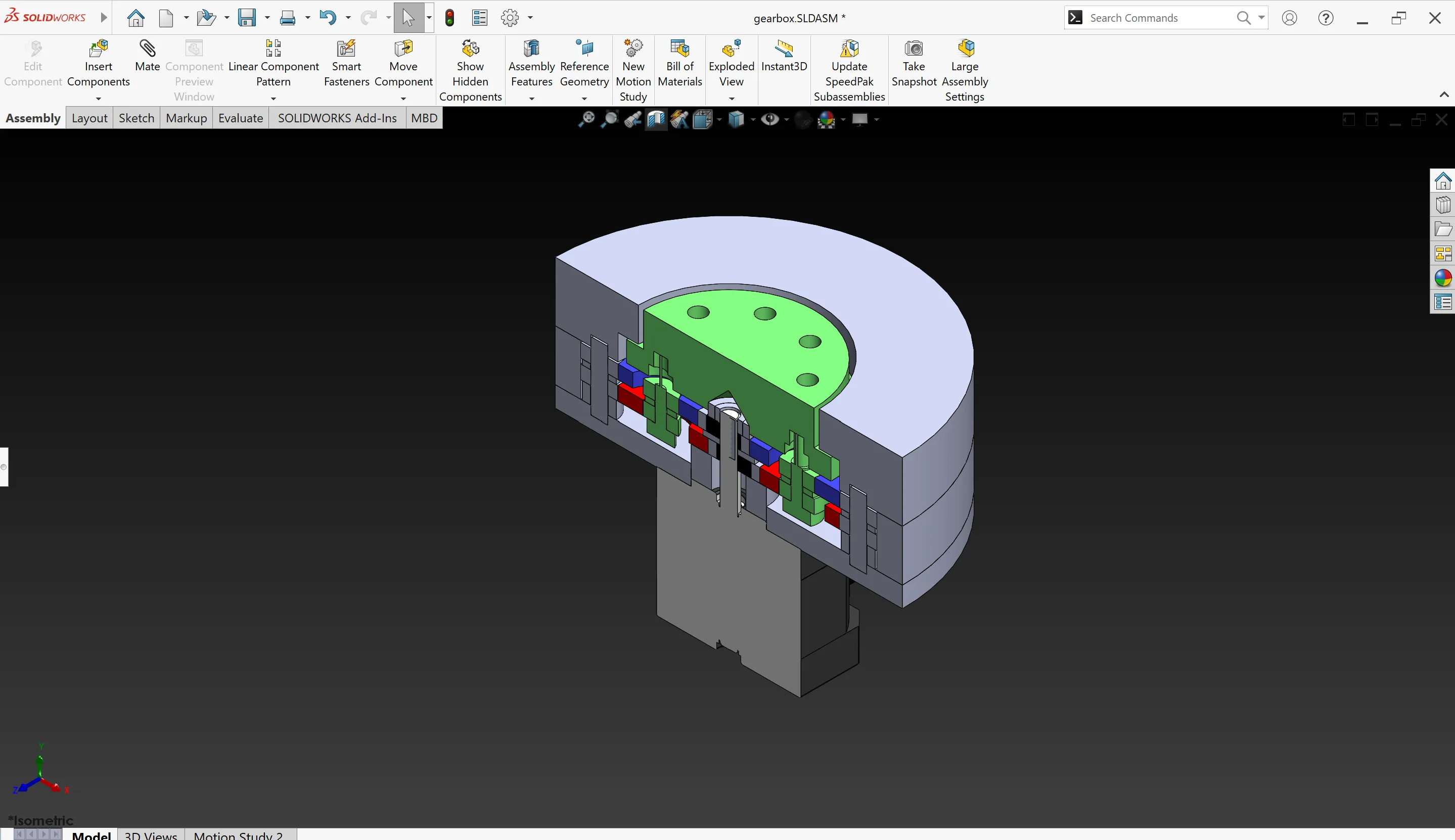

One of the key components we wanted to tackle was the cycloidal drive reducer/gearbox. We wanted to go with this design of gearbox due to its low backlash, small form factor, and high gear ratios. Of course, the backlash is extremely dependent on the precision/tolerances in manufacturing, but we wanted to see how good we could get the fits using mostly 3D printed parts and off-the-shelf hardware.

After spending many hours scouring the internet, studying YouTube videos, and reading scientific papers, we finally arrived at our first draft design. Unfortunately, there are several flaws, including missing bearings/supports and non-ideal fasteners, but our design ended up this way thanks to our biggest constraint as students: cost.

We will try to print and adjust tolerances as soon as possible, so keep an eye out for the next update!

P.S. we really wanted to go with brushless DC motors, but the cost of the motors and corresponding FOC drivers was just.. a little out of our budget. Currently, we only plan to have two of these cycloidal gearboxes for our base and shoulder joints and we plan to use lighter, cheaper servos rather than the NEMA17 steppers for our end effector.