Cycloidal Gearbox #2 - Robot Arm Project

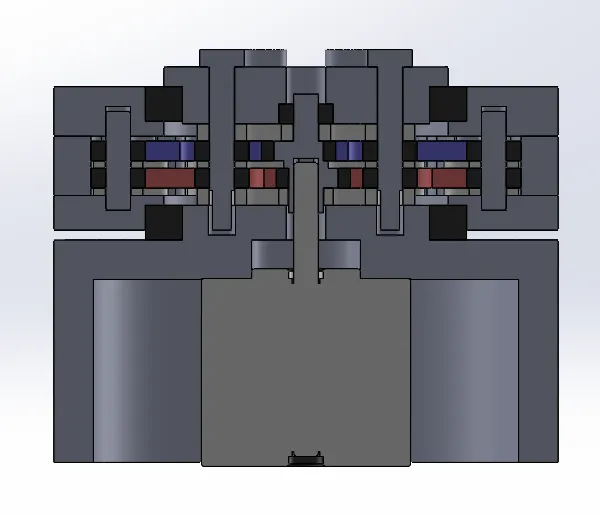

After a couple more 3D model design iterations, I decided it was time to print and test the first physical gearbox. The design has “fixed” cycloidal disks while the ring gear rotates as the output. The gear ratio is 10:1.

My brother and I printed several test prints to calibrate the XY-hole and XY-contour compensation values for our Bambu A1 printer and settled on an XY-hole compensation of 0.05 mm and an XY-contour compensation of 0 mm. This gave us relatively accurate-to-model dimensions, allowing us to press fit most of the bearings. We did have to manually add slight tolerances for certain parts though, such as the holes for the roller pins, the input shaft coupling, and the cycloidal disk profiles.

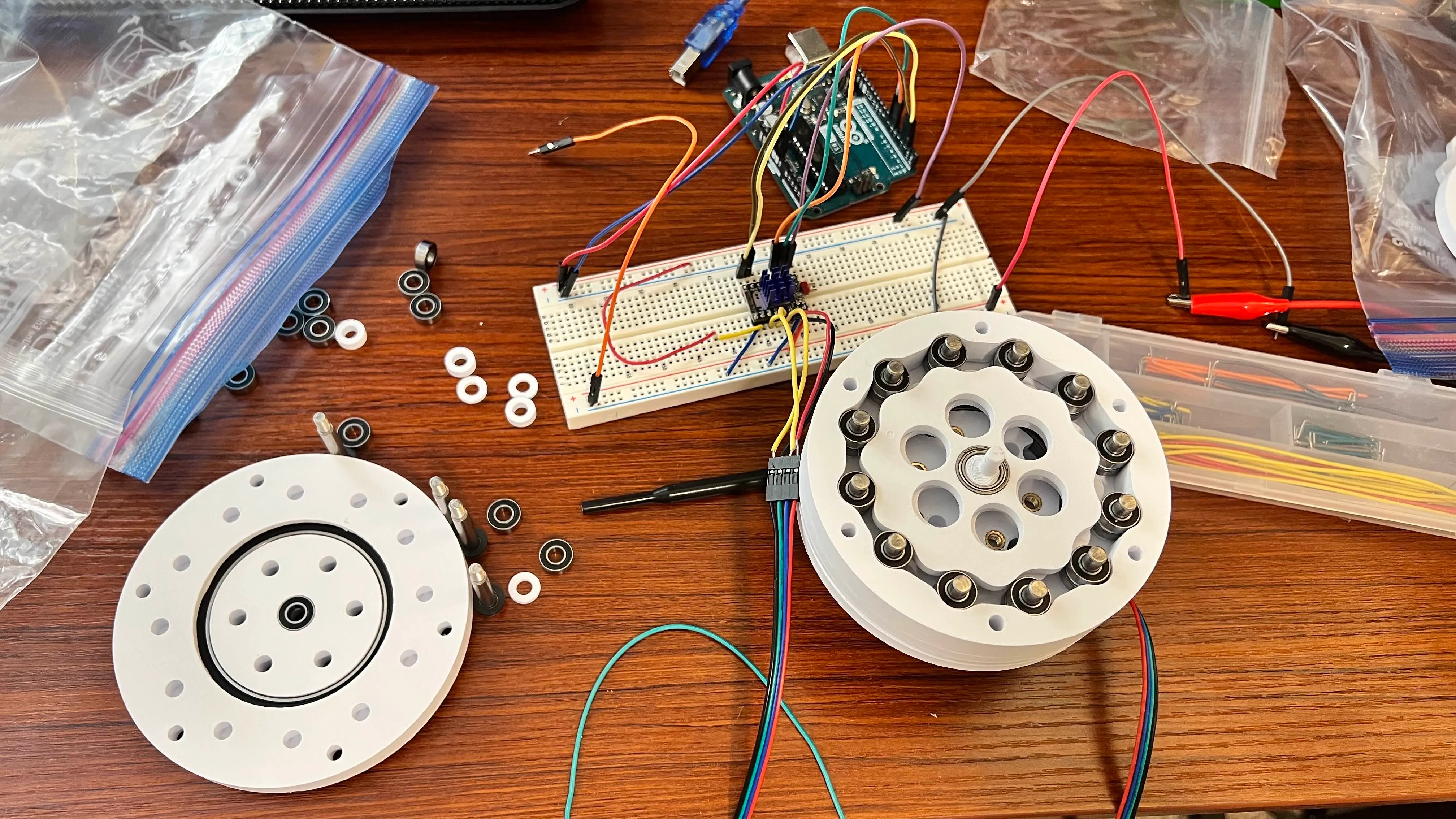

Once the parts had printed, we proceeded with the assembly. Although we had designed for manufacturability (DFM)/designed for assembly (DFA), there were still some kinks to work out. Specifically, it was difficult for us to disassemble the gearbox housing in case we needed to replace parts due to the press fits and it was difficult to fit the output pins through the cycloidal disks with the bearings, spacers, and the top cap. We will definitely keep these in mind for improvements for the next iteraion, adding features to help disassembly and perhaps replacing the output pins with simple shafts and fixing the bearings to the cycloidal disks themselves.

In order to test the cycloidal drive, we wired an Arduino and power supply to a TMC2209 stepper driver and ran a program using the AccelStepper library. Below is the result.

The driver is extremely quiet, especially compared to another driver we had previously tested (A4988). The torque was a little underwhelming, but it does seem realistic given that it was running in the 4 microstep setting. It was a little confusing to get the motor running and it seems like it should be able to run faster, but we will work on that for the next update. The gearbox is very backdriveable, but the tolerances can definitely be tighter as the backlash is very noticeable when turning the gearbox by hand (eyeballing maybe 1 degree).